- Home

- Science

- Our Work

- Air Pollution

- Agriculture, Farming and Pesticides

- Asthma and other Lung Diseases

- Coronavirus Pandemic (COVID-19)

- Exposure to Chemicals and Dust

- Exposure to Nanomaterials

- Human Exposure

- Neurodegenerative Diseases

- Musculoskeletal Disorders

- Occupational Cancer

- Sustainable Working

- Sustainability and Climate Change

- Stress, Wellbeing and Psychosocial Issues

- COVID-19 IOM Study of Face Coverings in Retail Environments

- Styrene Study

- PROTECT COVID-19 National Core Study

- Firefighters and Cancer – IOM Report

- MORtality Study of Former Professional Footballers in England and Wales (MORSE) Study

- Our Scientists

- Our Expertise

- Nano Material Services

- Development and Management of Data and Information Systems and Services

- Ergonomics Design and Evaluation

- Epidemiological Studies & Methods

- Exposure Assessment

- Health Impact Assessment (HIA) and Risk Assessment

- Policy Evaluations

- Study Design and Statistical Analysis

- Systematic Reviews and Meta-analyses

- Toxicology

- Workplace Cluster of Disease

- IOMLIFET

- IOM Scientists Advocate Tighter Standards for Airborne Dust at Work

- Research Project on Work Related Musculoskeletal Disorders

- Styrene Study

- Firefighters and Cancer – IOM Report

- IOM Library

- Contact our Research Experts

- Our Work

- Occupational Hygiene

- Case Studies

- Air Quality Sensors

- COSHH Assessment

- Dust Exposure

- Environmental Management

- Face Fit Testing

- Hand-Arm Vibration

- Indoor Air Monitoring

- Laboratory Animal Allergens

- Legionella Risk Assessment

- Local Exhaust Ventilation

- Noise Monitoring

- Thermal Exposure Monitoring

- Workplace Exposure Limits (WELs)

- Welding Fumes

- Remote Monitoring Services

- Formaldehyde Exposure Monitoring

- Biological Agent Exposure Monitoring in Waste Management

- Chromium VI

- Occupational Hygiene – Quick Quote

- Lab Services

- Asbestos and other Fibres

- Asbestos Sample Testing

- Asbestos Proficiency Testing

- Dust and Crystalline Silica

- Lead in Paint

- Metals, acid anions, acid gases

- Microbiology

- Pharmaceuticals

- Solvents & Other Organic Chemicals

- Hazard Assessment and Toxicology

- Dustiness Testing of Bulk Powders

- Lab Services Quick Quote

- Training

- Courses

- Face Fit Tester Training – Combined 2-day Course

- Face Fit Tester Training – Day 1 Qualitative Test Method

- Face Fit Tester Training – Day 2 Quantitative Test Method

- One Day Ventilation Maintenance Course

- BOHS Five Day Authorised Person (Ventilation) Course

- BOHS Three Day Competent Person (Ventilation) Course

- BOHS Two Day Competent Person (Ventilation) Refresher Course

- Contact our Training Team

- Courses

- Hospital Ventilation

- Authorising Engineer

- Dentistry Post Lockdown

- Design Review

- Independent Review

- Diathermic pen and Electro surgical tool testing

- Microbiological Monitoring

- Systems Refurbishment and Upgrade

- Validation and Verification Testing

- HSE COVID-19 Spot Check Inspections

- Training

- Contact Our Hospital Ventilation Experts

- Consultancy

- Our Company

- Contact Us

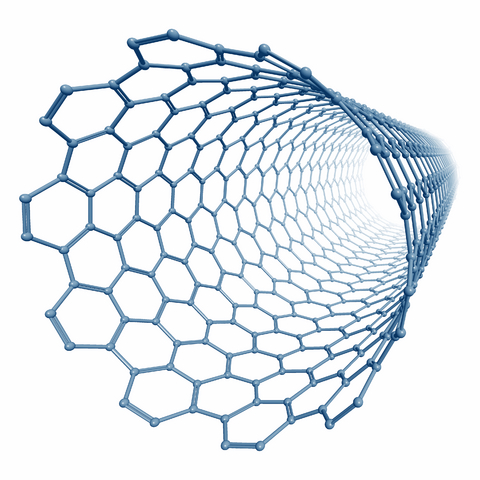

Manage nanomaterial risk with bespoke hazard testing

As nanomaterials continue to evolve and their use rapidly expands, fast and reliable hazard identification and assessment is needed to protect human health.

At the forefront of bespoke nanomaterial testing, IOM is addressing the hazards that exposure presents whether through inhaling, ingesting, or touching.

With clear and timely results, their evidence-based approach supports clients to keep their workforce safe, as well as the public and the environment, whilst enabling them to innovate and develop.

Discover IOM’s extensive nanomaterial testing capabilities today, improve your understanding, and minimise your risk no matter your industry.

Why the risk needs to be managed

With an external dimension or internal dimension/structure in the nanoscale, far different from their bulky counterparts, huge potential has opened-up for the use of engineered nanomaterials across a variety of industries including optics, electronics, manufacturing, cosmetics, and the medical field.

This rapid acceleration and development, along with often unique chemical and physical properties, means they often present an undetermined potential for adverse effects upon human health and a growing occupational concern.

Whilst there are no agreed WEL’s for nanomaterials, their manufacture and use are regulated under the Control of Substances Hazardous to Health Regulations 2002 (COSHH) whereby employers are obliged to protect their staff from exposure; there are, however, a growing number of recommended exposure limits for certain nanomaterials, including CNTs, fullerenes, Ag, and TiO2, as well as for quite generalised categories such as HARN and biopersistent/poorly soluble nanomaterials.

As a new technology, HSE’s advice when it comes to nanomaterials is to take a precautionary approach to all areas of risk management.

To continue innovating, developing, and using these materials it is critical to ensure their safety, by testing, evaluating exposure, and minimising risk.

Supporting this, many organisations are striving to achieve EU Chemical Strategy objectives to stay ahead of regulation and ensure that they can continue to be competitive for larger contracts.

These aim to deliver a safer, more sustainable way of working and are focused around:

- Innovative, safe, and sustainable chemical design

- Reduction of animal testing

- Improved speed, quality, and efficiency of chemical hazard and risk assessments

A scientific approach

Boasting a wealth of scientific and engineering experience and a trusted reputation, IOM is a leader in the understanding, assessment and control of hazards in the workplace.. Working alongside clients and research groups to create safe, healthy, and compliant environments.

Collaborating with UK and EU research groups, and the scientific community, IOM is in a unique position to offer comprehensive nanomaterial testing based on the latest regulatory developments and scientific understanding.

This up-to-date approach means that businesses are far better placed ensure their workers are safe, and to meet REACH and CLP regulations, test, and develop products appropriately.

Nanomaterial Testing Methods

Harmful exposure to nanomaterials occurs in a variety of ways from cleaning operations, equipment maintenance, weighing and mixing, packaging, accidental spillage, and incorrect disposal.

Using in vitro, ex vivo, and in silico techniques IOM assess the toxicological hazard of chemicals, nanomaterials, nano-enabled products, or advanced materials to determine where the threat to health lies.

Efficient and trusted New Approach Methods (NAMs) are applied to assess hazards posed from inhalation, dermal, and ingestion exposure to nanomaterials, including, but are not limited to:

- Cytotoxicity/viability

- Measurement of pro-inflammatory mediators (and other cell signalling processes)

- Measurement of reactive oxygen species and oxidative stress

- Assessment of material solubility (dissolution, bioelution, bioaccessibility, bioavailability)

Thanks to a multi-disciplinary approach, IOM can test either as an individual service, or as part of a bespoke testing suite in consultation with the client regarding a specific question/outcome, or to meet regulatory compliance.

This service is supported by IOM’s in-house professional team who provide clear and independent guidance around the test findings, risk assessment, control measures, and regulations.

Act Now

Nanomaterials present endless possibilities for a range of industries and consumer products, but in turn they present a risk to human health and the environment, the true nature of which currently remains unknown.

IOM’s hazard testing capabilities, alongside reliable material characterisation, ensure that clients can develop products using nanomaterials safely, avoid potential toxic hazards, and stay compliant.